Odelya offers cost-effective, variable, and customized solutions of structural steel tubing for many application areas with accordance to international standards.

Odelya® ERW Structural Steel Tubes with specially-composed chemical and mechanical properties, offer balanced and practical solutions for many constructional and industrial areas, from in-building designs to superstructure applications.

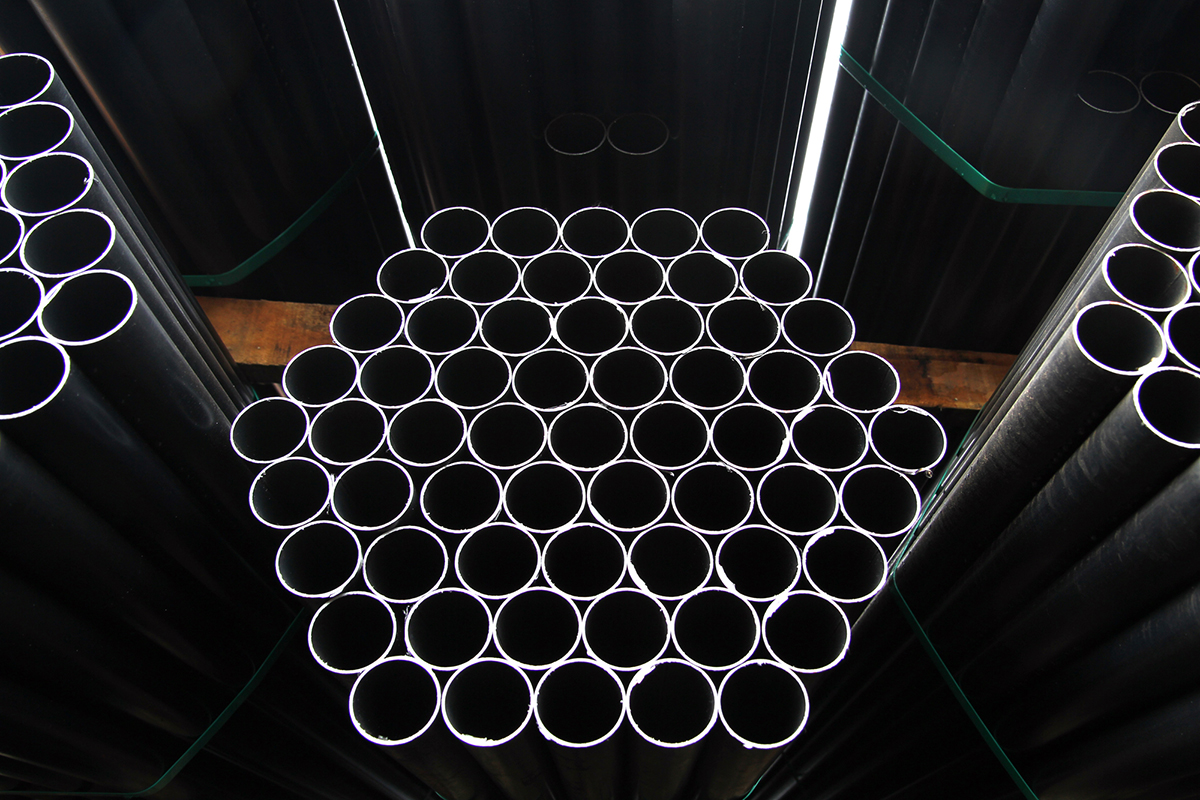

Produced with three typical shapes (circular, square, rectangular), other special shapes (such as elliptical, oval) are also available upon request.

Excellent strength properties, perfect distribution of material around the axis of Odelya® Hollow Sections and superior production quality, provide durability, bendability, and a light weight of steel structures.

Odelya® High Frequency ERW Hollow Structural Sections vary on their material types, surface conditions, process- ing types, and are available as: carbon or stainless, black (self-colour), surface-coated, galvanized, plain and bevelled-end…

Building and bridge construction, automotive industry, mechanical engineering, framework structures and other components for transportation vehicles, light and heavy duty machinery, building scaffolding structures, amusement parks and playground equipment, furniture, machine and agriculture tools, racks, elevators and platforms for vertical access, space frames, industrial structuring works, greenhouses, solar energy systems, guard rails for staircases, sports galleries, pedestrian walkovers, etc.

According to the requirements of the application, Odelya® Hollow Sections can be manufactured as, bare, black, self-coloured, painted, red primer painted, oiled, cold rolled, hot finished unpickled, hot rolled pickled steel with chosen protective coatings (‘galfan coating’ or ‘galvanizing –zinc coated’).